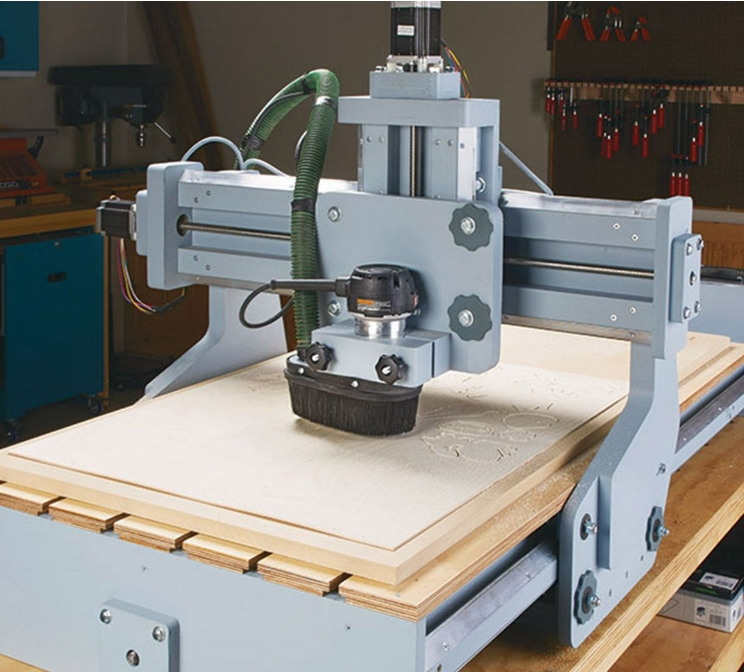

In the realm of modern manufacturing, CNC routing has emerged as a transformative force, seamlessly blending precision with creativity. Whether youre crafting intricate designs from medium-density fiberboard (MDF), delicately shaping aluminium, or working with the natural beauty of timber and advanced composites, the versatility of CNC routers offers endless possibilities.

Imagine a workshop where the roar of machinery harmonizes with the finesse of artistry—each cut executed with stunning accuracy, every curve capturing the eye. This technology is not just a tool; it is a bridge between innovation and craftsmanship, empowering designers and engineers alike to push the boundaries of their work.

Dive in as we explore the unique capabilities of CNC routers across various materials, revealing how they reshape industries and elevate creative potential to new heights.

Advantages of Using CNC Routers for MDF Processing

CNC routers offer a myriad of advantages when it comes to processing MDF, providing unparalleled precision and efficiency that can transform any woodworking project. With the ability to execute intricate designs with remarkable accuracy, these machines eliminate the human error that often plagues traditional cutting methods.

The versatility of CNC routers is unmatched; they can seamlessly transition between intricate patterns and large-scale cuts, all while maintaining consistent quality. Speed is another critical factor—jobs that once took hours can be completed in a fraction of the time, enhancing productivity and allowing for quicker turnaround on projects.

Furthermore, the waste reduction achieved through optimized cutting paths not only conserves materials but also contributes to a more sustainable approach to production. In essence, utilizing CNC routers for MDF processing ensures superior craftsmanship, saving time and resources while opening up a world of creativity.

Preparing MDF for CNC Cutting

Preparing MDF for CNC cutting is a crucial step that can significantly influence the quality of your finished project. First, choose high-quality MDF, ensuring it’s free from defects like warping or excessive moisture.

Next, cut your MDF sheets into manageable sizes—this aids both in handling and precision during the actual cutting process. Before loading your material onto the CNC machine, take the time to clean the surface thoroughly; even dust particles can lead to inaccuracies.

Additionally, consider applying a coat of sealer or primer, as this can not only protect the MDF from chipping but also enhance the finish of the final product. And don’t forget to double-check your CNC router settings—feed rates, spindle speeds, and bit selection all play vital roles in achieving clean cuts and smooth edges.

With careful preparation, your CNC cutting journey into the world of MDF turns into an engaging exploration of creativity and precision.

Best Practices for CNC Cutting MDF

When cutting MDF with a CNC router, attention to detail is paramount to achieve smooth edges and precise cuts. First, ensure that your machines feed rate and spindle speed are optimized for MDF’s density; a typical combination is a moderate feed rate with a high spindle speed to prevent burning and achieve cleaner cuts.

Use sharp, high-quality router bits designed specifically for composites to avoid fraying. Additionally, employing a comprehensive dust extraction system during the process not only keeps your workspace tidy but also enhances visibility and helps in maintaining the integrity of your cuts.

Dont forget to perform test cuts on scrap pieces before committing to your final design; this practice allows you to fine-tune settings and anticipate any potential issues. Lastly, always follow safety protocols—wear appropriate protective gear and ensure that the CNC machine is calibrated correctly to handle the unique properties of MDF.

Conclusion

In conclusion, CNC routing has revolutionized the manufacturing and fabrication processes for a diverse range of materials, including MDF, aluminium, timber, and composites. This versatile technology not only ensures precision and efficiency but also opens up new possibilities for intricate designs and custom projects.

Businesses and hobbyists alike can leverage CNC routing to achieve high-quality results that meet their specific needs. For those in the region seeking professional support, CNC routing services in Brisbane offer expert solutions tailored to a variety of applications. As CNC technology continues to advance, it will undoubtedly play an increasingly vital role in various industries, driving innovation and enhancing productivity.