Rust removal machines using lasers are an increasingly popular choice for removing rust from metal surfaces. These powerful tools use the power of light to cut through tough rust spots, leaving behind a clean surface in its wake.

But what is the science behind these amazing machines? This article will explain how laser rust removal works and why it\’s so effective. Well, look at the physics involved and some of the advantages of this technology over traditional methods like sandblasting or chemical treatments.

Finally, will discuss some safety considerations when using these powerful tools. Read on to learn more about laser rust removal!

Overview of Laser Rust Removal Machines

The overview of Laser Rust Removal Machines presents a comprehensive look at how these laser systems can be used to clean rusty surfaces. By focusing on the scientific principles underlying their function, this overview will explain why and how rust is removed using lasers.

It will further discuss the various types of laser available for use in rust removal processes and describe their advantages over traditional methods such as sandblasting or chemical treatments. Lastly, it will explain the safety protocols that should be followed when using these machines to prevent any potential damage to materials being treated.

In conclusion, Laser Rust Removal Machines offer an effective and safe way to remove rust from objects without damaging them in any way.

How Lasers Remove Rust

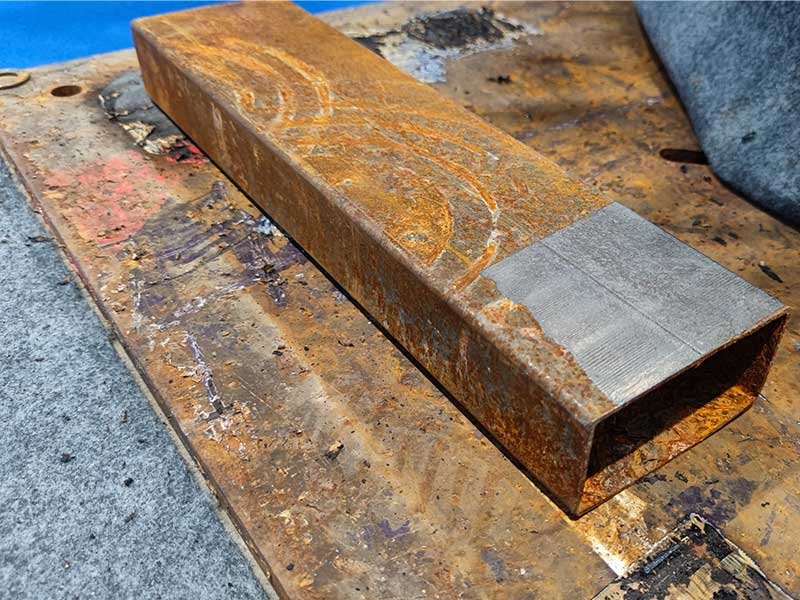

Removing rust is an important part of keeping metal surfaces safe and looking their best. However tackling this task manually can be a tedious, time-consuming job.

That’s why laser rust removal machines have been developed to do the work for you. To understand how these machines work, it’s important to look at the science behind them.

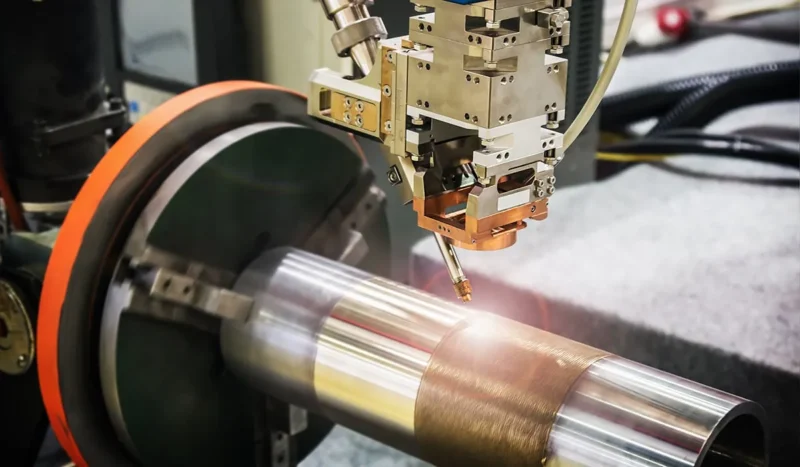

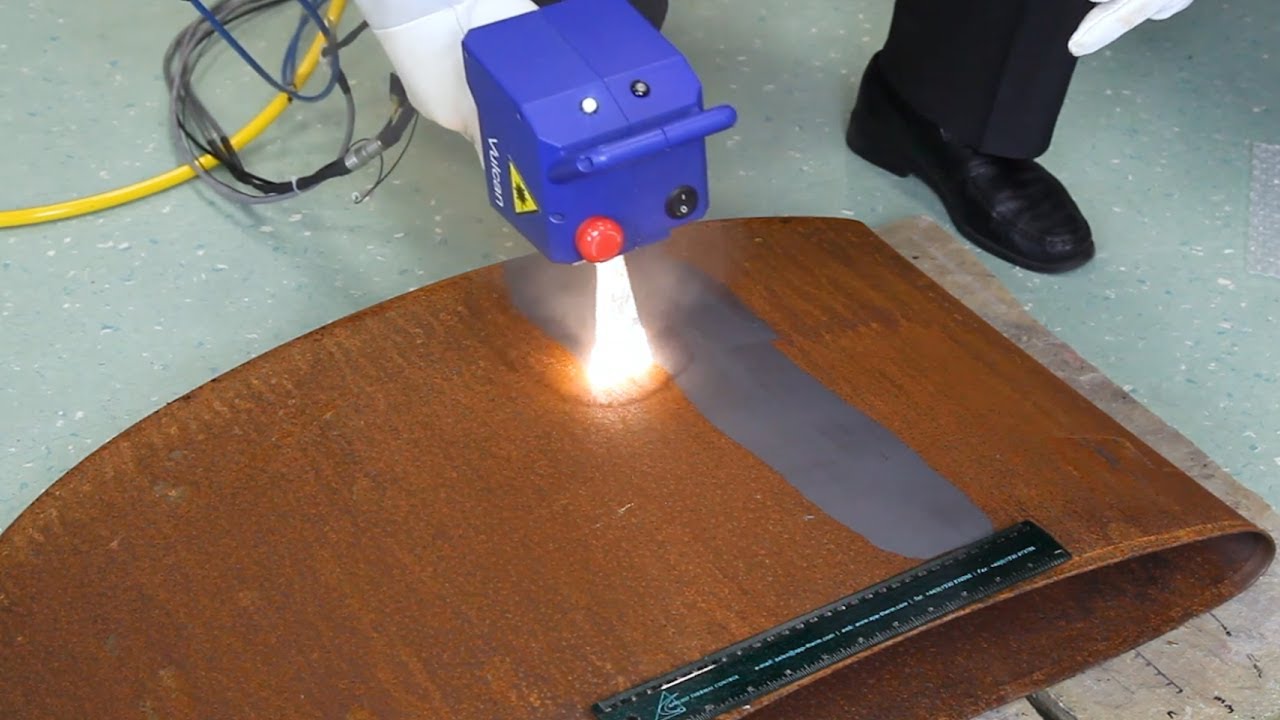

Lasers are used in combination with various chemicals and abrasives that work together to break down rust into small particles that can be easily removed from the surface of the metal object without damaging its finish or texture. The lasers target rust molecules on contact and release energy which vaporizes them so they can then be wiped away using a cloth or other cleaning materials.

By changing the amount of power within each pulse, users can adjust their settings for different levels of effectiveness depending on the depth of rust buildup they need to remove from any given surface area. Lasers also help speed up this process by ensuring that all areas are treated evenly and accurately without wasting time and effort trying to cover every corner manually.

The use of lasers means less physical labor is required when removing stubborn layers of corrosion, making it ideal for large-scale projects where manual efforts would take too long or require more expensive equipment like sandblasting tools which could cause excessive damage if not used properly. Laser technology has become increasingly efficient over recent years as advances in artificial intelligence help make automated systems ever more precise while still delivering consistent results with minimal error rates — something human workers simply couldn\’t match on their own!

Advantages and Disadvantages of Using Laser Rust Removal Machines

Laser rust removal machines are an increasingly popular way of removing rust from metal surfaces, offering several advantages over traditional methods. In this article, we’ll explore the science behind laser rust removal machines and outline the advantages and disadvantages of using them.

One of the primary benefits of laser rust removal is its precision. Lasers can be tuned to target specific areas with pinpoint accuracy, allowing operators to remove deep-seated corrosion without damaging surrounding materials or causing any collateral damage. This also means that laser rust removal is much faster than manual sanding or grinding techniques as it does not require extensive preparation and clean-up time.

Furthermore, lasers are more effective at penetrating hard-to-reach areas to completely eradicate all traces of corrosion from a surface. Despite these benefits, however, there are some drawbacks associated with using laser technology for rust removal too.

First off, while lasers offer precise control over their targets they can also cause permanent discoloration if used improperly – which could potentially ruin an entire piece being worked on if caution isn’t taken during operation! Additionally, due to their high power requirements, they tend to be expensive pieces of equipment and may not always be cost-effective for smaller jobs where manual tools would suffice instead. Finally, due to safety considerations lasers must usually be operated by trained professionals in a controlled environment – making them less practical for use outside industrial settings where access might be limited or restricted altogether.

Overall then while laser technology offers many advantages when it comes to removing corrosion from metal surfaces there remain some important factors that need considering before investing in such machinery – both financial and safety-related ones alike!

Conclusion

Laser machines are a great way to quickly and efficiently remove rust from metal surfaces. The science behind these machines involves the use of lasers to heat up and vaporize the rust particles, leaving clean, corrosion-resistant metal in its wake.

While laser technology has advanced considerably since its initial development, it remains an effective method for removing unwanted rust. Laser rust removal machines offer users an efficient and cost-effective solution to their problem, allowing them to restore any rusted surface to pristine condition with minimal effort.